Engineering Features That Eliminate Common Problems

Every design element addresses real-world performance challenges contractors face with standard soffit vents.

Extended Nose Design

The Critical Difference: Discharge Beyond the Building EnvelopeSoffitFlow's extended nose projects just beyond the fascia line, creating physical separation between exhaust discharge and passive intake vents. This extension represents the fundamental design innovation that eliminates recirculation—the primary cause of attic moisture problems in standard installations.

Performance Benefits

Professional contractors can guarantee bathroom exhaust installations actually remove moisture from the building envelope rather than simply relocating it within the attic space. This eliminates the most common source of mold-related callbacks and provides legal protection when moisture issues arise from other building envelope failures.

The extended discharge also creates positive pressure that deflects exhaust air away from the roof line, ensuring consistent performance regardless of wind conditions or seasonal temperature variations that affect natural convection patterns.

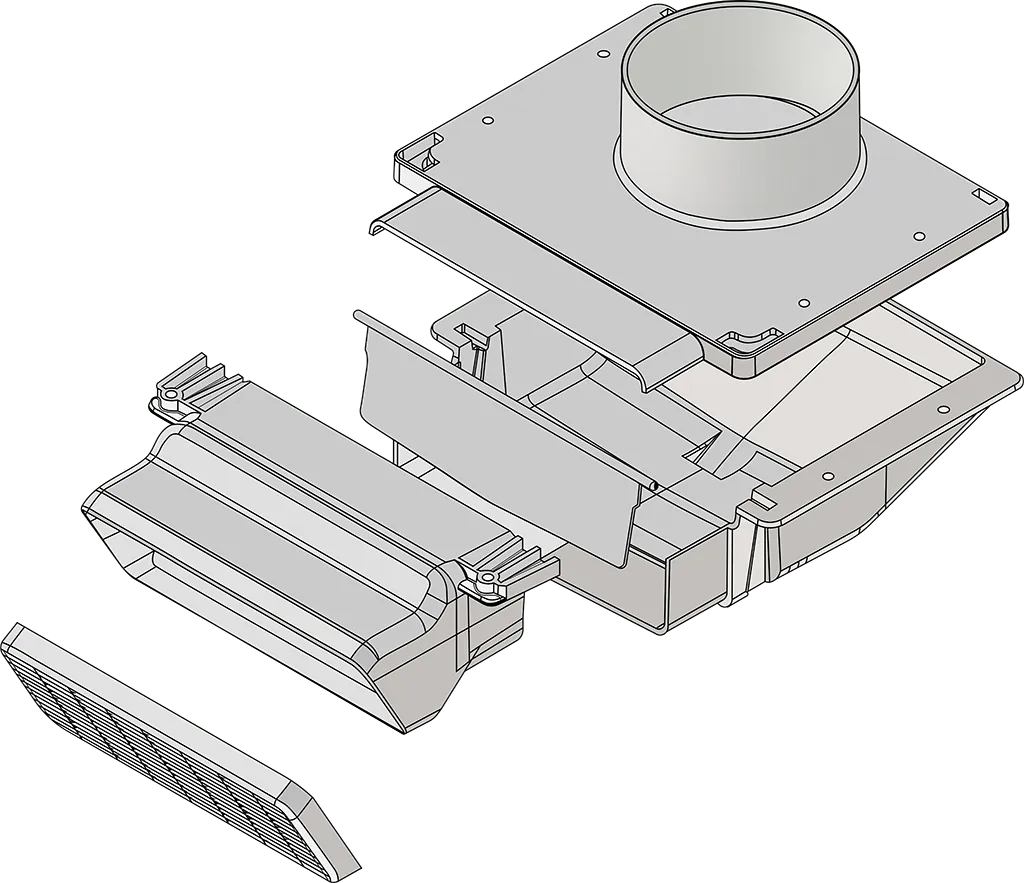

Precision-Positioned Collar System

Optimized Airflow Engineering for Proper Discharge VelocityThe 4-inch diameter collar positions toward the rear of the housing, working in conjunction with the V-shaped tapered bottom panel to create an acceleration zone. This engineered airflow path increases exit velocity compared to straight-through designs, improving dispersion effectiveness and reducing dwell time near the building envelope.

Installation Advantages

Installation AdvantagesStandard ductwork connections eliminate compatibility issues with existing rough-in procedures. The collar positioning accommodates normal installation tolerances while maintaining optimal airflow characteristics. Contractors can integrate SoffitFlow into existing workflows without modifying standard practices or requiring specialized training for installation crews.

The precision engineering also ensures consistent performance across units, eliminating the variability that creates callbacks when individual installations underperform due to manufacturing inconsistencies.

Gravity-Assist Damper

Reliable Backdraft Prevention Without Mechanical ComplexityThe gravity-assist damper opens automatically when airflow reaches 50 CFM and closes when the fan stops, preventing backdraft during negative pressure events. Unlike spring-loaded mechanisms that can fail due to corrosion or debris accumulation, gravity operation provides inherent reliability across the full operating range.

Operational Benefits Contractors can specify SoffitFlow with confidence knowing the damper will operate reliably throughout the product lifecycle without requiring periodic adjustment or replacement. The 50 CFM activation threshold accommodates standard residential bathroom fans from 50-110 CFM, eliminating compatibility concerns with typical installations. The damper design also prevents pest intrusion during non-operating periods while maintaining optimal airflow when the system is active. This dual functionality eliminates the need for separate backdraft preventers or pest screening that can reduce airflow performance.

Engineered Weep Hole Drainage

Condensation Management That Prevents Ice Damage and Water AccumulationThe precisely positioned weep hole at the housing base provides drainage for condensation that can form during normal operation. The location and sizing prevent water accumulation that could freeze in cold climates, causing housing damage or damper malfunction.

Climate Performance

In cold climates, water accumulation in exhaust terminations can freeze, blocking airflow or damaging housing components. The engineered drainage eliminates this failure mode, ensuring year-round operation without requiring seasonal maintenance or freeze protection measures.

For humid climates, the weep hole prevents standing water that could promote bacterial growth or create additional moisture sources near the building envelope.

Wildlife-Resistant Hinged Grill

Pest Protection With Maintenance AccessThe front-mounted hinged grill helps to prevent wildlife intrusion while maintaining easy removal for periodic cleaning and inspection. The hinge design eliminates the lost parts and difficult reassembly that plague removable grill systems, encouraging regular maintenance that preserves long-term performance.

Maintenance Advantages

Professional contractors can provide clients with simple maintenance procedures that don't require specialized tools or technical expertise. The hinged design encourages homeowner maintenance compliance, reducing callbacks related to performance degradation from accumulated debris or pest nesting.

The grill openings are sized to help prevent pest intrusion while minimizing impact on airflow performance. This balance eliminates the compromises contractors face with standard terminations that either restrict airflow or provide inadequate pest protection.

High-Density Polyethylene Construction

Material Science That Eliminates Common Failure ModesHDPE construction provides superior performance characteristics compared to standard ABS or PVC terminations. The material maintains structural integrity across temperature extremes from -40°F to 150°F without becoming brittle or losing dimensional stability.

Durability Benefits

Professional installations require materials that perform consistently throughout the building lifecycle without requiring premature replacement. HDPE's UV resistance prevents the embrittlement and cracking that plague standard plastic terminations exposed to direct sunlight.

The material's low moisture absorption rate prevents dimensional changes that can affect damper operation or create air leakage paths. This stability ensures the precision engineering tolerances remain consistent throughout the product lifecycle, maintaining optimal performance without requiring adjustment or replacement.

Chemical Resistance

Coastal installations face salt spray exposure that can corrode metal components and degrade standard plastics. HDPE's chemical resistance ensures performance in these challenging environments without requiring protective coatings or accelerated replacement schedules.

Industrial environments with airborne chemicals present similar challenges that HDPE construction addresses without compromise. Contractors serving these markets can specify SoffitFlow with confidence in long-term performance.

Manufacturing Quality

Made in USA Quality and ConsistencyPrecision injection molding ensures dimensional consistency across production runs, eliminating the variability that creates installation challenges or performance differences between units. USA manufacturing provides quality control and supply chain reliability that supports professional contractors' project schedules.

Professional Advantages

Consistent quality eliminates callbacks related to manufacturing defects or dimensional variations that affect installation. Professional contractors can rely on predictable performance characteristics and availability that supports project planning and client commitments.

USA manufacturing also provides responsive technical support and engineering assistance for challenging applications. Professional contractors have direct access to the engineering team for specification questions or custom application guidance.